Galvanised steel products have been around for hundreds of years. The process of galvanising is believed to have been discovered in India in the 4th century AD and was later discovered by Europeans in the 17th century when it had been used as armour for Indian armies.

These days, galvanised steel is everywhere. Most commonly used in the construction industry, galvanised products include support beams, piping, heating and air conditioning duct work, barriers and handrails. Galvanized steel is used to make outdoor grates used for industrial walkways street lights, beds, washtubs, buckets, nails, planter boxes and of course, gabion baskets.

Galvanisation is the process of applying a protective zinc coating to steel, to prevent rusting. The most common method is hot-dip galvanizing, in which parts are submerged in a bath of molten zinc. Galvanizing protects in two ways:

Source: Wikipedia

5mm gauge galvanised steel gabion baskets provide excellent protection against the Australian elements for many many years. When it comes to fully understanding the performance of galvanic protection of steel, the Galvanizers Association of Australia (GAA) are the domain expects. Since 1963, the GAA has been leading the way in providing Australians with information on galvanised products.

For more information on the performance of galvanised steel in Australian conditions, visit the Galvanizers Association of Australia.

The higher gauge of wire (thicker it is), the more coating is required to meeting international and Australian zinc coating regulations. 5mm thick wire (as supplied by Gabion Walls Australia) has a coating mass of 280 grams per square metre coating. This can be converted to a thickness using the following formula:

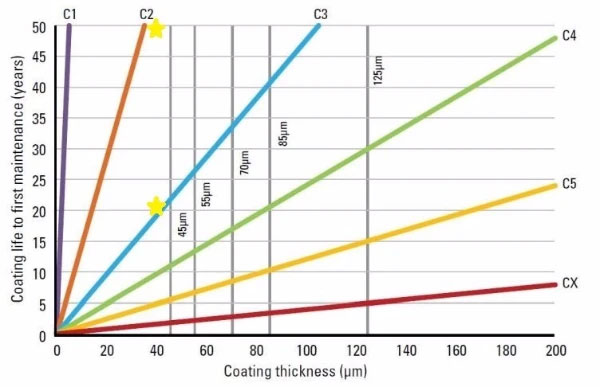

So 39.2 microns is the coating thickness. Remember this value, we need it for later.

Arriving at a defined life expectancy of your galvanised steel gabion basket will depend on a number of factors influencing the potential corrosion of the steel. Time of Wetness - This denotes the length of time the metal is covered by water allowing the corrosion process to take place. Salt in the Air - The closer you live to the ocean, the more salt in the air. Airborne salinity increases the potential for corrosion to occur. Pollution in the air - The amount of sulfur dioxide in the air will contribute to the degradation of the galvanised coating.

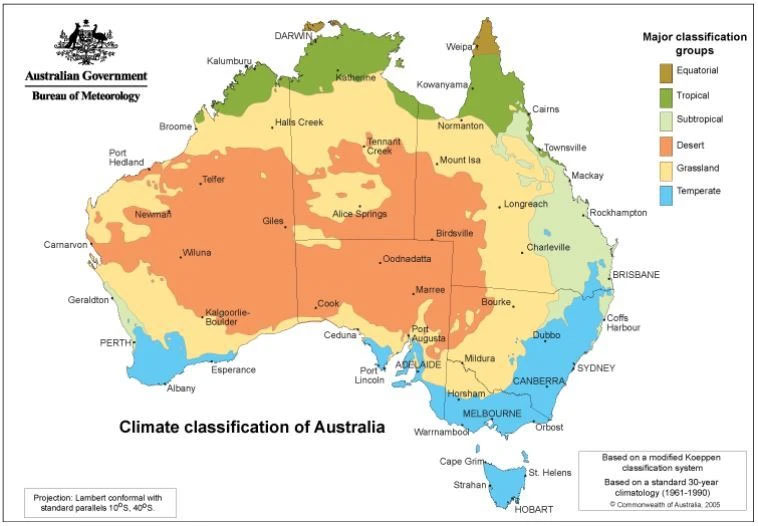

In summary, it comes down to where the gabion baskets will be located. Thankfully, many studies have been done over the last 50 years to help paint an accurate picture of what to expect. View the below map below and find out which classification your property falls:

Corrosive Category C1

Corrosivity = Very Low

Locations = Desert zone

Corrosive Category C2

Corrosivity = Low

Locations = Temperate zone with low pollution & Desert zone

Corrosive Category C3

Corrosivity = Medium

Locations = Temperate zone with medium pollution & Subtropical and tropical zones with low pollution

It is worth noting that the GAA have recognised that in Australia, pollution is so low in most environments that it is generally considered that it can be ignored, other than for specific industrial applications or extreme traffic examples.

If you live in South East Queensland or Northern NSW, your property will be classified in corrosive category C2 or C3. There are other corrosive ratings however they have been excluded from this article as they are not relevant. If you wish to learn more about the different corrosive ratings of galvanised steel, I recommend reading the Atmospheric Corrosion Resistance of Hot Dip Galvanized Coatings available from the GAA website here.

The below graph shows the life expectancy before first maintenance is required. In a C3 category, it is 20 years and C2 category, it is 50+ years remembering that the coating thickness of the steel wire is 39.2 microns.

Using galvanised steel as the material for your gabion basket makes sense. Information published by the Galvanizers Association of Australia have shown installations in Queensland and Northern NSW will be maintenance free for at least 20 years in the worst case conditions and 50+ years for installations further inland and away from salt air.

Gabion baskets are a simple product and don't need to be overcomplicated with intricate and expensive coatings that add little benefit. Galvanised steel is the simple and proven finish to high quality steel gabion baskets for your rock retaining wall, wire mesh cage or landscape feature.